e-Production

Project description

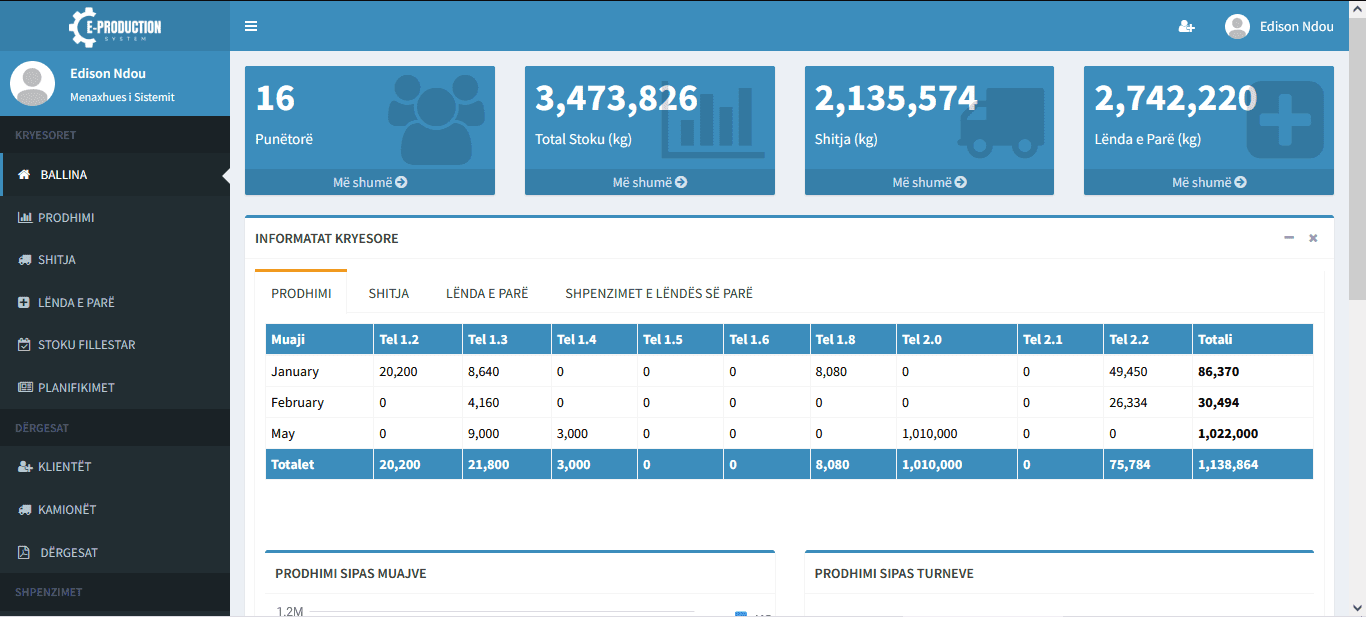

This project is a fully customized ERP (Enterprise Resource Planning) solution designed for manufacturing companies to manage and streamline their entire operation from procurement to production, sales, and reporting. It provides complete control and visibility over raw materials, production lines, human resources, finances, and logistics. The system enables seamless management of customer orders and supplier purchases, allowing users to track order status, delivery timelines, and payment progress while also generating and sending invoices automatically. It offers real-time tracking of raw materials, semi-finished goods, and finished products, with automatic stock updates after purchases, consumption, and production, as well as alerts for low stock and reordering needs.

Companies can define raw materials and link them to specific products or production lines, making it easy to track material usage per product or batch. Production orders can be created and managed efficiently, with the ability to assign machines and workers to specific tasks and track progress, quantity, and quality in real time. The system includes functionality for adding and monitoring manufacturing machinery, tracking usage time, machine output, and scheduling maintenance. Worker management is fully integrated, allowing employee registration, task assignment, productivity tracking, and performance evaluation based on production output.

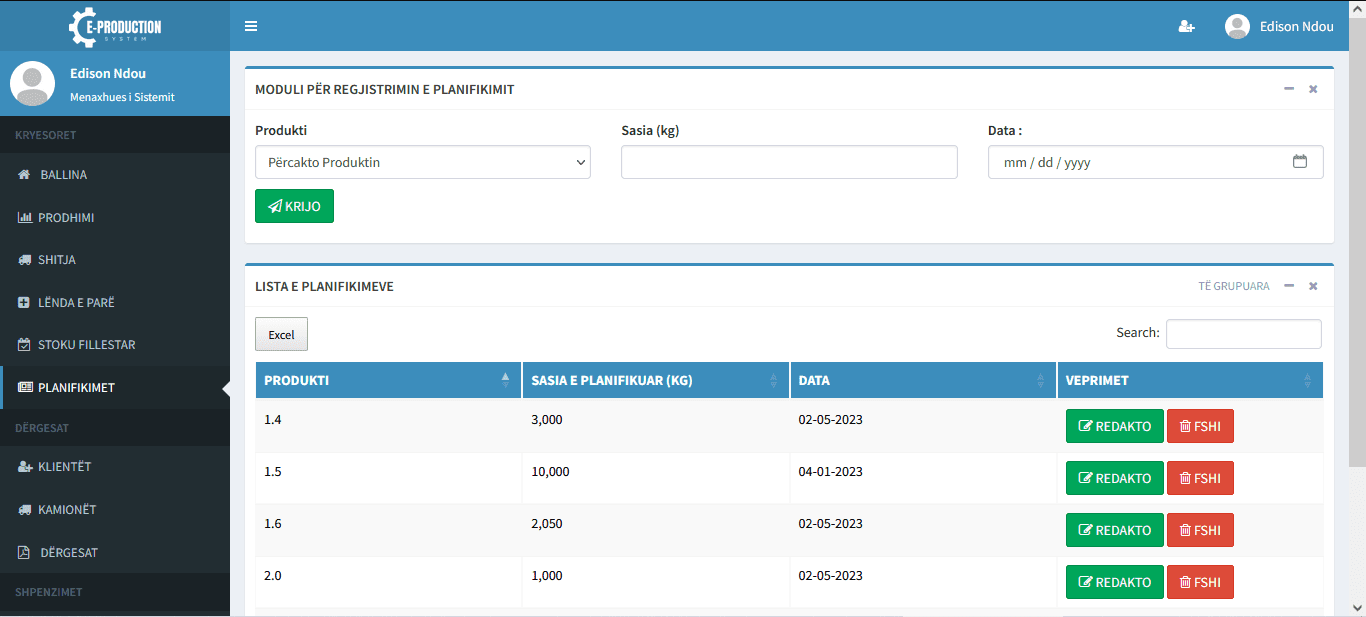

Contracts and invoices are managed internally, with automatic invoice generation for completed orders and direct links to sales and delivery workflows. The platform monitors both fixed and variable expenses, calculates profit margins by product or client, and gives businesses full control over production and operational costs. With built-in planning and scheduling tools, businesses can create detailed production plans, compare planned versus actual performance, and identify delays, resource gaps, or bottlenecks. Delivery operations are handled smoothly, including delivery scheduling, logistics partner management, and delivery tracking, all connected to invoicing and stock management.

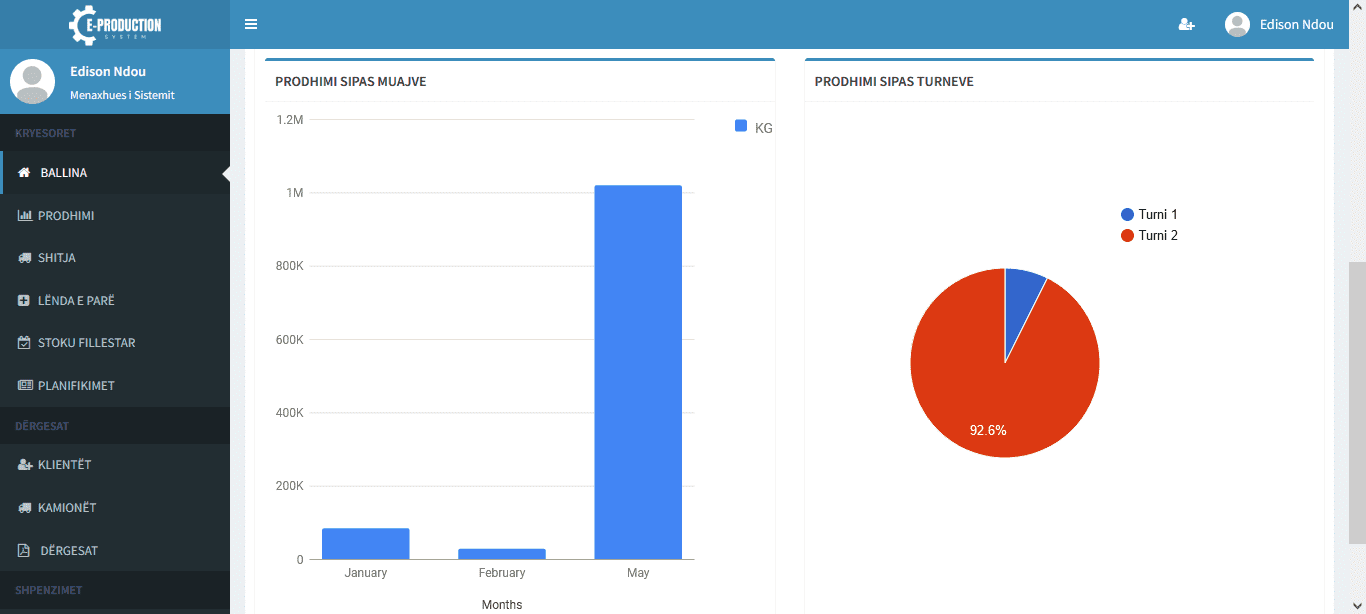

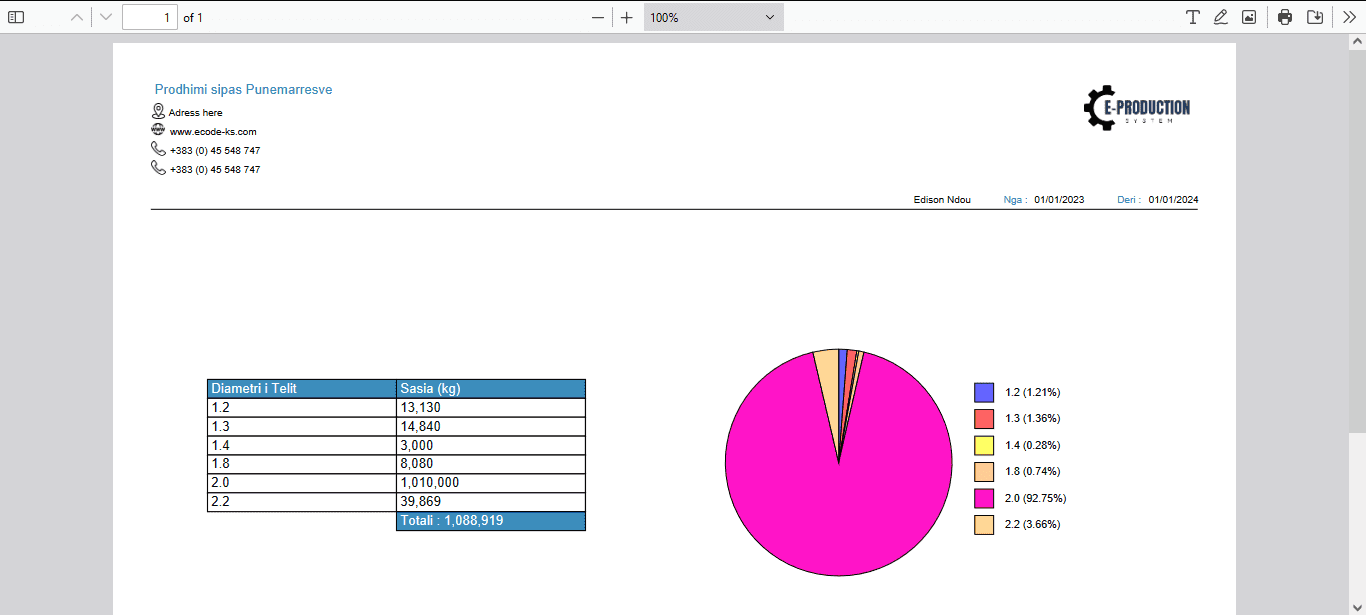

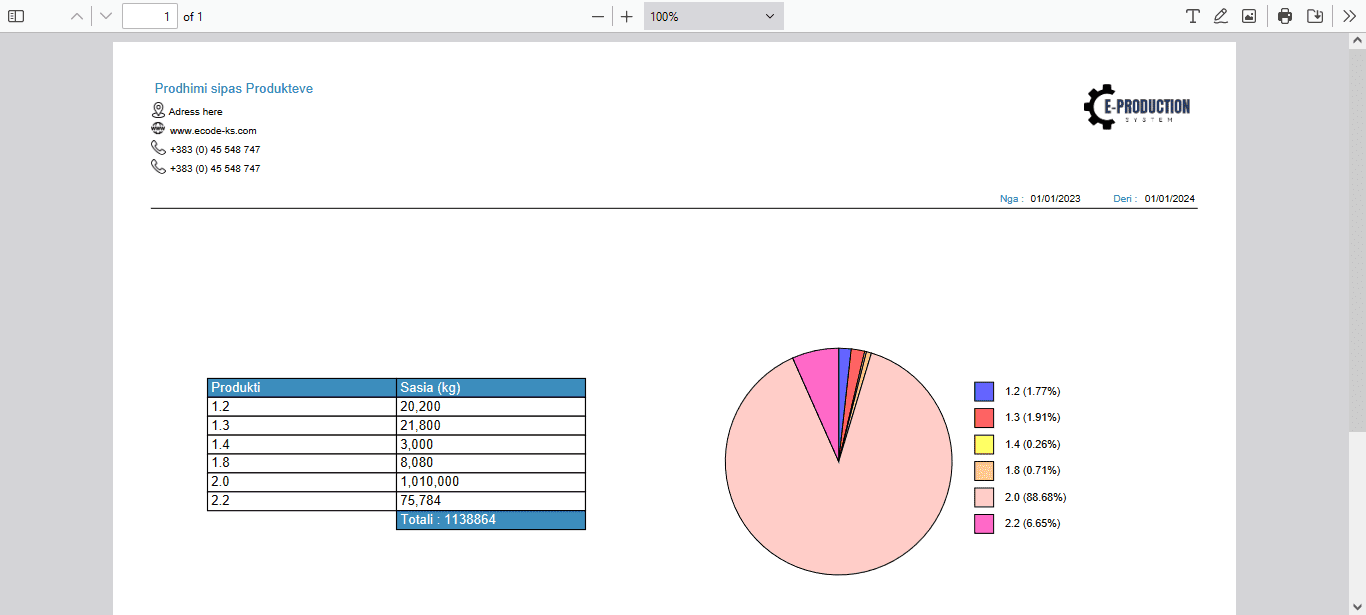

Client data and order histories are organized in a CRM module, with the flexibility to customize pricing by client and streamline communication. An advanced reporting engine delivers deep insights through sales reports by product, customer, and date; production reports by worker, machine, and product; stock movement and consumption data; planning vs. actual execution reports; expense tracking; profit analysis; and a high-level factory performance dashboard.

This ERP system delivers increased productivity through automation and centralized data, reduces human error across critical processes, and provides full traceability of materials, products, and labor. With real-time insights, managers can make faster and smarter decisions. The system is scalable and ready to support business growth, new locations, and expanding product lines. It offers a powerful digital backbone for any modern factory looking to improve efficiency, accountability, and long-term performance.

Companies can define raw materials and link them to specific products or production lines, making it easy to track material usage per product or batch. Production orders can be created and managed efficiently, with the ability to assign machines and workers to specific tasks and track progress, quantity, and quality in real time. The system includes functionality for adding and monitoring manufacturing machinery, tracking usage time, machine output, and scheduling maintenance. Worker management is fully integrated, allowing employee registration, task assignment, productivity tracking, and performance evaluation based on production output.

Contracts and invoices are managed internally, with automatic invoice generation for completed orders and direct links to sales and delivery workflows. The platform monitors both fixed and variable expenses, calculates profit margins by product or client, and gives businesses full control over production and operational costs. With built-in planning and scheduling tools, businesses can create detailed production plans, compare planned versus actual performance, and identify delays, resource gaps, or bottlenecks. Delivery operations are handled smoothly, including delivery scheduling, logistics partner management, and delivery tracking, all connected to invoicing and stock management.

Client data and order histories are organized in a CRM module, with the flexibility to customize pricing by client and streamline communication. An advanced reporting engine delivers deep insights through sales reports by product, customer, and date; production reports by worker, machine, and product; stock movement and consumption data; planning vs. actual execution reports; expense tracking; profit analysis; and a high-level factory performance dashboard.

This ERP system delivers increased productivity through automation and centralized data, reduces human error across critical processes, and provides full traceability of materials, products, and labor. With real-time insights, managers can make faster and smarter decisions. The system is scalable and ready to support business growth, new locations, and expanding product lines. It offers a powerful digital backbone for any modern factory looking to improve efficiency, accountability, and long-term performance.